Shenghong's 16 million tons/year refining and chemical integration project is progressing smoothly! All the core equipment of the faucet device is installed in place

Release time: 2021-02-01 Click on the quantity:1529On January 18, according to Dongfang Shenghong (000301.SZ) news, its 16 million tons/year refining and chemical integration project's leading device-the vacuum tower of the atmospheric and vacuum distillation unit was successfully hoisted at one time, marking the core equipment of the plant All are in place, laying a solid foundation for the smooth start-up of the project.

It is understood that Dongfang Shenghong's refining and chemical integration project is a key project of the national "Petrochemical Industry Planning and Layout Plan" and a leading project in Lianyungang's world-class petrochemical industry base. The construction scale of the project is 16 million tons/year oil refining, 2.8 million tons/year aromatics, 1.1 million tons/year ethylene and other downstream products, and supporting 300,000 tons of crude oil terminal, 3 million cubic meters of storage and other projects, with a total investment of about 67.7 billion Yuan is the private manufacturing project with the largest investment amount in the history of Jiangsu Province.

It is reported that after the Shenghong Refining and Chemical Project is completed and put into operation, it will greatly make up for the short supply of China's ethylene, aromatics and other bulk basic chemical raw materials, and promote the formation of a complete new high-end "crude oil-aromatic hydrocarbon/ethylene glycol-polyester-chemical fiber". The textile industry chain also provides raw material guarantee for the subsequent "chain extension" of strategic emerging industries such as new energy, new materials, electronic chemicals, biotechnology, etc. It is of great significance to promote the transformation and upgrading of China's petrochemical industry and achieve high-quality industrial development.

The refining and chemical decompression tower with a total weight of 1,717 tons and the largest single set of processing capacity in China was successfully hoisted at one time

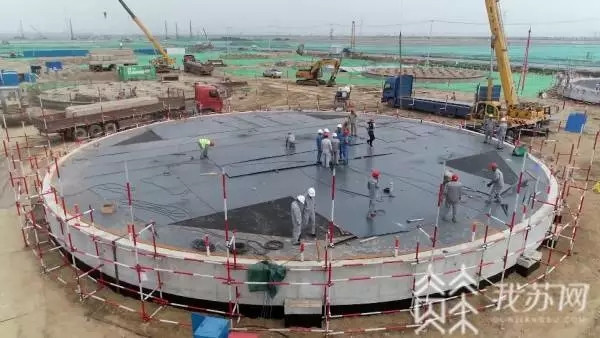

The pressure reduction tower hoisted this time is 58 meters high, 14 meters in diameter, and 1,717 tons in total weight. It is the largest diameter tower in the whole plant and is currently the largest single set of refining and chemical pressure reduction tower in China. The vacuum tower is mainly used to fractionate and produce light wax oil, heavy wax oil, vacuum residue and other components under reduced pressure, and provide secondary processing raw materials for downstream devices. The successful lifting of the vacuum tower means project construction Critical progress has been made. Yu Huiyong, general manager of Shenghong Refining & Chemicals, said that the current Shenghong Refining & Chemical Integration Project is progressing smoothly. More than 10,000 builders on the construction site are fully promoting civil construction, equipment installation, and terminal construction.

Up to now, the pile foundation construction has basically been completed, the construction of the first-level pipe network has exceeded 70%, the civil construction rate has reached more than 90%, the installation of more than 200 equipment has been completed and has entered the peak of installation, and the administrative office building, staff canteen, and frozen water station have been officially put into use , Steel structure installation and process pipeline prefabrication have been fully launched. The various constructions on the site are highly intersected and highly efficient, and the project construction site is changing day by day.

According to Zhang Shilun, general manager of the Project Department of Shenghong Refining and Chemical (Lianyungang) Co., Ltd., the next step will be to promote other equipment and further install process pipelines. It is planned to complete the delivery of the atmospheric and vacuum unit on June 30. On 26th, the oil intake target of the atmospheric and vacuum unit was achieved.

It is understood that the total investment of the Shenghong Refining and Chemical Integration Project is about 67.7 billion yuan. It is a key project of the national "Petrochemical Industry Planning and Layout Plan" and the largest private manufacturing project in the history of our province. After the project is put into production, it can refine 16 million tons of oil annually. At present, more than 90% of the equipment foundation construction of the whole plant has been carried out, and the important foundation constructions of the heating furnaces, towers, and reactors have been completed one after another. At the same time, the construction of the Shenghong Refining and Chemical Wharf is also accelerating. One crude oil berth of 300,000 tons and four liquid chemical berths of 50,000 tons have completed the main project two months in advance.

Yu Huiyong said that the company strictly fulfills the main responsibility for environmental protection. In the design, construction and operation of the Shenghong Refining and Chemical Project, in accordance with the target positioning of "environmental protection, green development" and the concept of circular economy and clean production, the process route and design are optimized Plan, select high-quality equipment and raw materials, optimize and adjust the energy structure, improve the quality of chemical products and fuel oil, and strengthen energy-saving and emission-reduction measures for each device. The environmental protection investment of the entire project reached 4.3 billion yuan, accounting for nearly 6% of the total investment. The amount and proportion of environmental protection investment are both at the leading level in the industry, ensuring the advanced nature of the project in terms of environmental protection technology and equipment, and laying a foundation for green and environmental protection operations. solid foundation.

Strictly implement the "three simultaneous" system of supporting environmental protection facilities and the main project at the same time during the construction of the project, and put into operation at the same time, and also hire a professional environmental supervision agency for the whole process of project design, construction, trial production, and completion acceptance Carry out supervision to ensure the implementation of the "three simultaneous" measures in environmental protection.

The construction of major projects requires sufficient funding. According to Yu Huiyong, the 19.08 billion yuan capital required for Shenghong's refining and chemical project will be fully in place by 2020. In August 2020, the syndicated loan for the Shenghong Refining and Chemical Integration Project was officially signed in Nanjing, with a total financing amount of 41.5 billion yuan, and the current total withdrawal amount has reached 17.5 billion yuan, meeting the project construction funding needs. The remaining 24 billion yuan of subsequent syndicated loans will also be gradually used in accordance with the project fund plan. Sufficient construction funds will effectively guarantee and support the early completion of the refining and chemical integration project, early production and early results. It is understood that after the project is put into production, it is expected to achieve an average annual operating income of about 92.5 billion yuan, an average annual net profit of about 9.4 billion yuan, and a profit and tax exceeding 20 billion yuan. The company expects the project to be completed and put into operation in 2021.

Copyright: Zhejiang Everstand Mechanical Engineering Co.,Ltd Tel:+86-574-86111527 E-mail:nbcy2006@163.com Power by mdcm