Chief Scientist of Wison: Without BDO, how can PBAT come from? Supporting raw materials will become the key to victory!

Release time: 2021-03-17 Click on the quantity:2795● The China Olefins and Feedstock Diversification Forum 2021 hosted by ASIACHEM will be held in Huizhou, Guangdong from March 24-25;

●This forum will arrange an inspection of Huizhou New Materials Industrial Park, a 100 billion-level park that is focused on building in Huizhou.

● The chief scientist and technical director of Wison Engineering will attend the meeting and give an excellent report on "C4 1,4-Butanediol (BDO) Technology and Market".

●BDO is in tight supply and its price has soared. As one of the important raw materials of PBAT, it has unexpectedly become a card neck product.

● For production companies, how to make full use of their own resources and lay out high value-added product lines near consumption areas will be the key for companies to stand out in the face of more intense industrial competition and obtain excess returns.

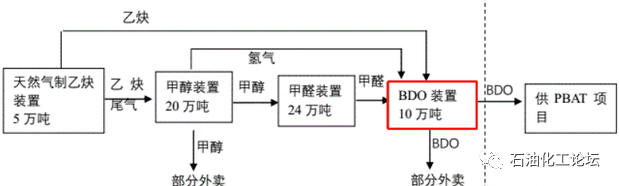

● The industrial route of using olefin derivatives and by-product C4 as upstream raw materials to produce BDO and extend it to PBAT is highly feasible for companies with raw material advantages.

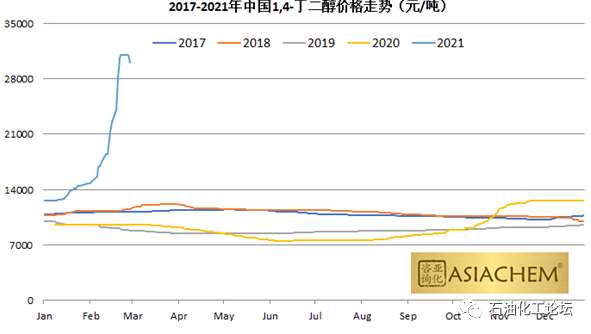

In the beginning of 2021, the price of 1,4-butanediol (BDO) soared all the way, breaking through the 30,000 yuan/ton mark in late February, a record high. The current global supply of BDO is extremely tight, causing downstream production to be greatly affected.

There are two main reasons for the price increase:

In the second half of 2020, the BDO downstream PTMEG to spandex industry chain is extremely hot, and the market is out of stock or supply is tight, supporting the upward price;

The dark horse of the industry-biodegradable plastic PBAT has entered a period of accelerated development under the background of favorable policies, and the demand for BDO has increased significantly. It takes about 0.43 tons of BDO to produce one ton of PBAT.

It is reported that an industry insider said that there is no reason why BDO will fall below 20,000 this year and next year. The normal adjustment is 35,000-25,000 yuan, maintaining the price range of 25,000-28,000.

China's BDO industry is mature, and downstream traditional industries such as PTMEG-spandex, PBT, GBL, TPU, etc. have maintained stable development. In the past few years, the downstream consumption structure of BDO has been relatively stable. Under the new version of the ban on plastics, the scope and strength of the ban on plastic products far exceed the previous restrictions on plastics, and biodegradable materials such as PBAT and PLA have ushered in a broad market. The downstream PBAT/PBS field of BDO is showing a good momentum of development, and its proportion in the downstream consumption structure of BDO is gradually increasing.

Statistics show that the newly added capacity of PBAT under construction and planning in China is about 6 million tons, and companies such as Hengli Petrochemical, Wanhua Chemical, Dawn Co., Ltd. and Ruifeng High Materials have entered the game. In theory, it can consume 2.6 million tons of BDO.

In the future, the centralized release of PBAT production capacity, on the one hand, the demand for BDO will rapidly increase, and its proportion in the downstream consumption of BDO will increase rapidly, and it is expected to rank among the top two downstream BDOs; on the other hand, it will intensify the industrial competition pattern. The core competitiveness lies in the level of integration.

Wanhua Chemical (600309) invested a 100,000-ton BDO plant in Meishan, Sichuan. The project entered the environmental assessment stage in January. According to the EIA announcement, Wanhua invested in the BDO project mainly for supporting the 60,000-ton PBAT project in Sichuan. This layout was truly praised by industry insiders, who believed that its extraordinary forward-looking nature was indeed admirable. Obviously, the relatively affluent raw materials in the early stage may not be able to keep up with the new demand of PBAT, and the matching of raw materials will become an important factor in the future competition in the PBAT industry.

BDO has a variety of production technologies. At present, there are five main industrial production processes: Reppe method, butadiene/acetic acid method, propylene oxide method, n-butane/maleic anhydride direct hydrogenation method and n-butane/cis Anhydride esterification hydrogenation method.

The Reppe method is also known as the acetylenic aldehyde method. This process is a traditional method for producing BDO, which is divided into a classic method and an improved method.

The butadiene/acetic acid process was successfully developed by Japan's Mitsubishi Chemical Corporation in the 1970s.

The propylene oxide process was developed by Japan's Kurali Company, and LyondellBasell, which mainly produces propylene oxide, obtained a patent license for this technology and built a plant in Texas, USA.

N-butane/maleic anhydride direct hydrogenation method is a production method that combines the gas-phase oxidation method of n-butane to maleic anhydride and the hydrogenation technology of maleic anhydride.

The n-butane/maleic anhydride esterification hydrogenation method is to oxidize n-butane to maleic anhydride under the action of a catalyst, and then the maleic anhydride undergoes an esterification reaction with ethanol under the action of a catalyst to produce diethyl maleic anhydride; The ethyl ester is hydrogenated under the action of a catalyst to generate BDO, γ-butyrolactone and THF. By adjusting the process conditions, the ratio of BDO, γ-butyrolactone and THF can be changed.

For olefin producers, especially coastal olefin producers, how to make full use of their own resources and lay out future scarce product lines near the consumption area will be the key for companies to stand out in the face of more intense industrial competition and obtain excess returns. .

From a long-term perspective, the BDO market has a bright prospect, and the price will be high for a long time. The profit space of BDO's various processes is gradually opened and continues to expand. Using olefin derivatives and by-product C4 as upstream raw materials, the industrial route of producing BDO and extending it to PBAT is highly feasible for companies with raw material advantages.

The China Olefins and Raw Material Diversification Forum 2021, hosted by ASIACHEM, will be held in Huizhou, Guangdong on March 24-25; this forum will arrange an inspection of Huizhou New Materials Industrial Park, a 100-billion-level park that will be built by Huizhou; The chief scientist and technical director of Wison Engineering will attend the meeting and give an excellent report on "C4 1,4-Butanediol (BDO) Technology and Market".

Source: Petrochemical Forum

China Olefins and Feedstock Diversification Forum 2021

(March 24-25 · Huizhou, Guangdong)

Conference Name: China Olefins and Feedstock Diversification Forum 2021

Meeting time: March 24-25, 2021

Location: Huizhou, Guangdong

Meeting scale: 100-120 people

Visit and inspection: Huizhou New Material Industrial Park, a 100-billion-level park that Huizhou focuses on building

Conference theme: industrial policy, light hydrocarbon resources, market supply and demand, technology and economy, project layout, olefin downstream

Organizer: ASIACHEM Consulting

Sponsors: Honeywell UOP, Zake (China) Engineering Equipment Co., Ltd., China Aviation Development Chengdu Chengfa Keneng Power Engineering Co., Ltd., Pile Fan Trading (Shanghai) Co., Ltd.

Schedule

Wednesday, March 24, 2021

◇ Research and Judgment on the Development Trend of China's Olefin Feedstock Lightening——Sinochem International (Holdings) Co., Ltd.

◇ Technical progress and industrialization practice of chemical production by direct cracking of crude oil-Tsinghua University

◇ Development and application of CNPC's million-ton-level ethylene complete process technology-China Huanqiu Engineering Corporation Beijing Branch

◇ Opportunities and suggestions for the development of olefin derivatives under the new situation——Wanhua Chemical (Yantai) Petrochemical Co., Ltd.

◇ Title to be determined-Zheke (China) Engineering Equipment Co., Ltd.

◇ The development of the PDH industry and UOP's new generation of high-performance PDH process-Oleflex-HoneywellUOP

◇ Solutions for downstream high value-added products of ethylene: α-olefins, POE, HDPE-Institute of Chemistry, Chinese Academy of Sciences

◇ Development status and development discussion of metallocene polyethylene——Sinopec Qilu Branch Research Institute

◇ C4 1,4-butanediol technology and market (n-butane-maleic anhydride-BDO, butadiene-BDO)-Wison Group

◇ Analysis and thinking on the development trend of the global olefin industry——Petrochemical Research Institute of China National Petroleum Corporation

◇ Title to be determined-China Aviation Development Chengdu Chengfa Keneng Power Engineering Co., Ltd.

◇ Title to be determined-Huizhou New Material Industrial Park

◇ More topics are being confirmed

Thursday, March 25, 2021

Business inspection: Huizhou New Material Industrial Park, a 100 billion-level park that Huizhou focuses on building

The "Plastic Recycling and Energy Chemical Carbon Neutrality Forum 2021" sponsored by ASIACHEM will be held in Huizhou on March 25-26, focusing on relevant policies, technologies, and markets.

Subject

Plastic pollution control and carbon neutrality "14th Five-Year" policy trend

Plastic production and the challenge of carbon peak and carbon neutral goals

Plastic recycling in Japan, the European Union, and the U.S.

Domestic and international advanced plastic recycling technology and industrial application

Analysis of the development prospects of recycled plastics and degradable plastics

PET recycling technology and downstream enterprise application situation

PP/PE/PC recycling technology and application prospects

Waste recycling, recycling cost and economic analysis

Evaluation criteria and application scenarios of recycled materials

Circular economy park development ideas and commercial demonstration

The status quo and trend of recyclable design ideas

Industry tour (to be confirmed)

Copyright: Zhejiang Everstand Mechanical Engineering Co.,Ltd Tel:+86-574-86111527 E-mail:nbcy2006@163.com Power by mdcm