SABIC cooperates with bp plastic recycling technology to produce 30% ethylene propylene by 2030

Release time: 2021-03-22 Click on the quantity:1742

Plastic Recycling and Energy and Chemical Carbon Neutrality Forum 2021 will be held in Huizhou, Guangdong on March 25-26, and will visit Huizhou New Material Industrial Park on March 25.

SABIC China experts will give a report on the conference: SABIC TRUCIRCLE TM Sustainable Solutions-Responding to the Industry's Circular Economy Challenges

In early March 2021, overseas media reported that SABIC and bp signed a new agreement to jointly promote the circular economy in the petrochemical activities of the Gelsenkirchen Chemical Park in Germany. Based on the long-term cooperative relationship between the two companies in the production base, the new cooperation will help increase the production of certified recycled products. These recyclable products will be made into raw materials from used mixed plastics, thereby reducing the need for petrochemical plants. Of fossil resources.

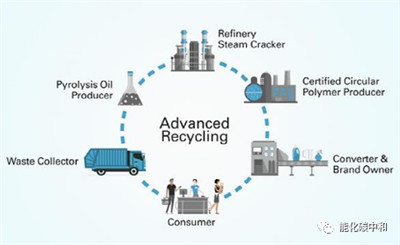

——Advanced recycling converts waste plastics into pyrolysis oil

Certified recyclable polymers are part of SABIC’s TRUCIRCLE™ product portfolio. They are produced using advanced recycling technologies to convert inferior mixed plastics and used plastics (incineration or landfill) into pyrolysis oil. The oil can be used as an alternative raw material for traditional fossil materials. It will be processed at bp’s Gelsenkirchen refinery and then used by SABIC at the Gelsenkirchen polymer plant to produce certified recyclable products.

The final material has the same characteristics as the original polymer, and the plastic can be recycled over and over again without losing any characteristics or properties. After successful trials in December 2020, the production of polymers using alternative raw materials began at the beginning of this year.

"Advanced recycling allows us to increase the production of sustainable materials and use the earth's resources wisely, while reducing the use of conventional methods such as landfilling and burning." SABIC's vice president of PE and sales said: "Advanced Recycling plays a vital role in the current recycling mix because it can extract value from plastic waste streams that have traditionally been neglected or discarded."

bp and SABIC have decades of cooperation on petrochemical products at the Gelsenkirchen plant, which is the starting point of the value chain of the chemical industry network in the northern Ruhr region. Gelsenkirchen's oil refinery and petrochemical plants play an important role in the chemical industry in Germany's most populous state of North Rhine-Westphalia. bp operates one of Germany's largest olefin plants with a capacity of approximately 2 million tons.

"This is an important milestone in our vision. By 2030, we will use sustainable and recyclable raw materials to achieve up to 30% of ethylene and propylene production," said the vice president of bp Europe and Africa Refining and Specialty Products Solutions.

——Basic chemicals and recyclable polymers certified by ISCC+

bp certified basic chemicals and SABIC certified cyclic polymers are recognized by the International Sustainability and Carbon Certification (ISCC+) program, which certifies the content and standards of the entire value chain from the source to the final product. ISCC+ certification applies to the so-called "mass balance system", which means that for every ton of round raw material that is fed into the cracker and replaces the fossil-based raw material, one ton of product can be classified as recyclable.

Recyclable polymers are part of SABIC TRUCIRCLE's product portfolio and services for recyclable innovations. The TRUCIRCLE product portfolio covers recyclability design, mechanical recycling products, certified circular products for recycling waste plastic raw materials, certified renewable products for bio-based raw materials, and closed-loop programs to recycle plastics into high-quality applications.

——SABIC empowers China's sustainable development

SABIC is a world-renowned diversified chemical company with operations in more than 50 countries around the world, and its products cover many fields such as chemicals, general and high-performance plastics, agricultural nutrients and steel. After more than 30 years of hard work in the Chinese market, China has become one of SABIC's most important strategic markets in the world, contributing about 20% of the company's global turnover. At present, SABIC has established factories in Shanghai, Guangzhou and Chongqing. Its business scope covers 14 cities in China and has more than 1,500 employees.

For the "13th Five-Year Plan", SABIC has always insisted on starting from practical actions, strengthening the company's unremitting efforts to promote cross-regional cooperation, empowering China's sustainable development, and actively responding to the establishment of a "domestic cycle as the main body, domestic and international cooperation". The new development pattern of "recycling and mutual promotion" will help China to build a new journey of a socialist modern country in an all-round way and start the next magnificent five years.

SABIC Shanghai R&D Center

Stay true to your original aspirations, deepen your sustainable development strategy

Sustainable development is one of the core contents of SABIC's "Vision 2025". In fact, the origin of the chemical industry was originally to strengthen the sustainability of oil use. The Saudi government founded SABIC that year with the original intention of making better use of the by-products produced during oil refining. After SABIC was completed, through innovative production processes, the crude oil-associated gas that was burned out in vain was converted into precious chemical raw materials.

Stick to its original intention, SABIC has always insisted on leading the trend of sustainable development worldwide as an industry pioneer. In 2019, SABIC took the lead in publishing a report on the Sustainable Development Goals that correspond to the United Nations’ 17 Sustainable Development Goals and meet the common concerns of the international community, and selected 10 goals based on its own characteristics as the company’s development focus, looking forward to leading innovative solutions through sustainable development The development of the program better meets global needs.

In order to effectively realize these sustainable development goals, SABIC has completed more than 170 plans with a total investment of more than 1.2 billion US dollars. At the same time, SABIC has always been committed to facing the world's sustainable development challenges, and has formulated six major directions of the company's sustainable development strategy: improving resource utilization efficiency; reducing greenhouse gas emissions and energy utilization intensity; committing to and supporting environmental health Safety; enable technological innovation of products and processes; encourage the development of circular economy; strengthen integrity control.

According to local conditions, SABIC has also launched a series of innovative solutions in China's packaging, transportation and new energy industries to help local customers achieve their sustainable development goals by creating products with fewer consumables and lighter weight. Working with SAIC-GM, SABIC has launched the world's largest LEXAN polycarbonate rear triangular window for automobiles, which can reduce weight by up to 40% compared with glass windows, which can help reduce greenhouse gas emissions. The MINI Countryman lightweight instrument panel bracket optimized by SABIC assisted BMW was awarded the SPE Automotive Innovation Award in the category of Interior Interiors. In addition, in response to China’s booming e-commerce industry’s growing demand for packaging solutions, SABIC has also jointly developed innovative foam packaging solutions with Ino Packaging, one of the leading manufacturers in China’s packaging industry, to make packages more Lighter, stronger and more durable.

Sustainable development is one of the core contents of China's 13th Five-Year Plan. As a company with global responsibility, SABIC has a complete set of practical experience recognized by the International Association of Chemical Manufacturers, which can accurately help China achieve sustainable development. By actively carrying out transformation and upgrading, creating value based on market and customer needs and promoting the strategy of diversification of raw materials, SABIC is confident that it has sufficient strength to achieve rapid iteration of sustainable products and solutions, and continue to consolidate its leading position in the industry.

At the same time, SABIC also actively organizes and participates in food safety-related seminars, supports and assists in reviewing various standards drafted by the Chinese Ministry of Health, and shares the results with member companies of the International Association of Chemical Manufacturers (AICM). Regarding process safety, SABIC continued to carry out relevant management guidance and training for chemical professionals and college students. In terms of ensuring product safety, SABIC’s product management team distributed tens of thousands of product compliance letters covering 7,000 products to downstream users to promote product safety compliance throughout the value chain.

Through this series of continuous efforts, SABIC has not only firmly established an industry leader in sustainable development, but also made outstanding contributions and leadership to China’s chemical industry, as well as the guiding principles of responsible care throughout the company’s operations. The efforts of the activities have been widely recognized by all walks of life. In April 2019, SABIC was once again awarded the "Responsible Care Leadership Award" by the International Association of Chemical Manufacturers (AICM). This is the fourth consecutive time that SABIC has won the top industry award from AICM after receiving the AICM "Responsible Care Merit Award" twice in 2013 and 2015 and the "Responsible Care Leader Award" in 2017.

TM

In addition, it is particularly worth mentioning that at the 2019 German Plastics and Rubber Industry Exhibition (K2019), SABIC innovatively launched a cycle solution product series-TRUCIRCLETM. Across four highly innovative but completely different technical fields, TRUCIRCLE® covers almost all SABIC recyclable materials and technical solutions, which can provide strong support for the advancement of circular economy and create a new value chain.

Strengthen the recyclable design of the product, reduce and thin the original packaging design while maintaining the same performance, and improve the recyclability and recyclability of plastic products, such as avoiding dark coloring and changing the material density; designing as little as possible Layers or structures that cannot be separated; use more easily recyclable materials; improve and upgrade the seal package design to reduce waste.

Take the washing powder packaging bag as an example. Due to the different performance requirements of the surface and inner layer materials, the washing powder packaging bag is usually composed of a multi-layer structure. However, due to the difference between the surface layer and the inner layer material, there are great difficulties in recycling. The SABIC BOPE solution provides unlimited possibilities for the realization of a single material. In the BOPE/PE structure, the surface layer BOPE meets the requirements of printing and stiffness, the inner layer of blown film PE has excellent heat sealability and toughness, and the full PE structure can easily achieve complete recycling.

Physical recycling: direct recycling after consumption is suitable for blended products that contain a high proportion of recycled materials to improve processing and product performance; and for resins that can improve recycled performance. While meeting the specific needs of different market segments, the product formula is optimized to maximize the content of recyclable materials.

In short, physical recycling is the process of breaking the well-known waste such as plastic bottles into plastic particles, adding other materials to make new plastic products. These plastics produced by physical recycling processes are usually used in household and daily use fields, such as the packaging of detergents, disinfectants and other products. A few days ago, SABIC actively launched the "Bag-to-bag" (BAG-2-BAG) project, which cleans the used transport packaging bags into base particles and then uses them for reproduction.

Chemical recovery: Recyclable polymers. Through chemical steps, waste plastics are directly "returned to their original form", and then re-entered into the cracking device to "start from scratch" to produce plastics. SABIC is a recycled polymer made from mixed plastic waste through a chemical recycling method and has been certified by ISCC. Its performance is no different from traditional products. It has been widely used to develop innovative, high-quality and safe packaging solutions.

For example, SABIC helped Unilever become the world’s first food brand to use recycled plastic packaging. The packaging comes from SABIC’s newly developed and certified recyclable impact-resistant polypropylene PP for frozen food; in addition, SABIC FLOWPACT polypropylene impact copolymer is also used. Used to manufacture soup powder packaging boxes for professional kitchens.

The bio-based renewable polymer SABIC is certified by ISCC. It is a renewable polymer product series based on raw materials that do not conflict with the food chain. It aims to reduce the use of fossil fuels. The bio-based raw materials used do not contain animal oil and palm oil ingredients. The waste ingredients from the paper industry have the same performance as traditional products and have a lower carbon footprint throughout the product life cycle. This solution can ensure that the safety and performance of the product itself is not affected, and there is no need to modify the downstream production process, which not only saves costs, but also helps to alleviate the global food crisis and the earth's climate change.

Based on pioneering measures such as TRUCIRCLE®, SABIC focuses on "sustainable development" throughout the entire corporate value chain and cooperation with all parties in the industry chain. From upstream raw materials to operations, customers, use phases and recycling after the end of the product life cycle, SABIC is committed to creating a true "closed loop" of plastics.

SABIC TRUCIRCLE® Circulation Solution Product Series Showcase

China Olefins and Feedstock Diversification Forum 2021

(March 24-25 · Huizhou, Guangdong)

Conference Name: China Olefins and Feedstock Diversification Forum 2021

Meeting time: March 24-25, 2021

Location: Huizhou, Guangdong

Meeting scale: 120-140 people

Visit and inspection: Huizhou New Material Industrial Park, a 100-billion-level park that Huizhou focuses on building

Conference theme: industrial policy, light hydrocarbon resources, market supply and demand, technology and economy, project layout, olefin downstream

Organizer: ASIACHEM Consulting

Sponsors: HoneywellUOP, Zheke (China) Engineering Equipment Co., Ltd., China Aviation Development Chengdu Chengfa Keneng Power Engineering Co., Ltd., Pile Fan Trading (Shanghai) Co., Ltd.

Schedule

Wednesday, March 24, 2021

◇ Research and Judgment on the Development Trend of China's Olefin Feedstock Lightening——Sinochem International (Holdings) Co., Ltd.

◇ Technical progress and industrialization practice of chemical production by direct cracking of crude oil-Tsinghua University

◇ The latest progress of CNPC's million-ton ethylene complete process technology and its promotion and application-China Huanqiu Engineering Corporation Beijing Branch

◇ C4 1,4-butanediol technology and market (n-butane-maleic anhydride-BDO, butadiene-BDO)-Wison Group

◇ Opportunities and suggestions for the development of olefin derivatives under the new situation——Wanhua Chemical (Yantai) Petrochemical Co., Ltd.

◇ Upgrading and expansion of clean combustion technology in olefin industry——Zake (China) Engineering Equipment Co., Ltd.

◇ The development of PDH industry and UOP's new generation of high-performance PDH process-Oleflex-Honeywell UOP

◇ Solutions for downstream high value-added products of ethylene: α-olefins, POE, HDPE-Institute of Chemistry, Chinese Academy of Sciences

◇ Development status and development discussion of metallocene polyethylene——Sinopec Qilu Branch Research Institute

◇ Analysis and thinking on the development trend of the global olefin industry——Petrochemical Research Institute of China National Petroleum Corporation

◇ Sinopec's complex raw material million-ton-level ethylene complete technology research and development and industrial application-Sinopec Engineering Construction Company

◇ A new generation of high-efficiency axial compressor based on aero engine technology-China Aviation Development Chengdu Chengfa Keneng Power Engineering Co., Ltd.

◇ Introduction to the development of Huizhou New Material Industrial Park-Huizhou New Material Industrial Park

◇ More topics are being confirmed

Thursday, March 25, 2021

Business inspection: Huizhou New Material Industrial Park, a 100 billion-level park that Huizhou focuses on building

The "Plastic Recycling and Energy and Chemical Carbon Neutrality Forum 2021" sponsored by ASIACHEM will be held in Huizhou from March 25 to 26, focusing on relevant policies, technologies, and markets.

Subject

Plastic pollution control and carbon neutrality "14th Five-Year" policy trend

Plastic production and the challenge of carbon peak and carbon neutral goals

Plastic recycling in Japan, the European Union, and the U.S.

Domestic and international advanced plastic recycling technology and industrial application

Analysis of the development prospects of recycled plastics and degradable plastics

PET recycling technology and downstream enterprise application situation

PP/PE/PC recycling technology and application prospects

Waste recycling, recycling cost and economic analysis

Evaluation criteria and application scenarios of recycled materials

Circular economy park development ideas and commercial demonstration

The status quo and trend of recyclable design ideas

Industry tour (to be confirmed)

Copyright: Zhejiang Everstand Mechanical Engineering Co.,Ltd Tel:+86-574-86111527 E-mail:nbcy2006@163.com Power by mdcm