Plugging project with pressure:

Quickly and effectively eliminate leaks from the production system without stopping.

Suitable for chemical industry, oil refining, thermoelectric, metallurgy, plastic, chemical fiber and other industries.

Temperature range: -180℃~600℃

Pressure range: -1Mpa to 35Mpa

Medium: water, high temperature steam, hydrogen, ammonia, chlorine, phosgene, carbon monoxide, natural gas, heat medium oil, strong acid, strong base, benzene and other hydrocarbons and most of the media

Pipe parts: flanges, straight pipes, elbows, tees, valves, stuffing boxes, tanks and other special equipment bodies

(Before construction) DN2700X15 kg propylene

After Construction

(Pre construction) leakage of valve body and flange butene at 3 "x20kg - 110C

After construction

(Pre construction) 6”x20kg 250℃ Steam flange leakage

After construction

(Pre construction) 3'' x180kg 280℃ Steam Straight pipe leakage

fixture

After construction

(under construction) 4'' x280kg 300℃ leakage of self sealing ring of high pressure valve

After construction

(Pre construction) 280kg 300℃ leakage of self sealing ring of high pressure valve

After construction

(Pre construction)1-1/2''x 170kg 210℃ Steam valve leakage

After construction

(Pre construction)16''x 16''x 8'' x6kg 180℃ Steam Three-way leakage and valve body leakage

After construction

(Pre construction) 1''x 7kg -10℃ HCL Valve body corrosion

After construction

(Pre construction) 6''x 7kg 50℃ Acids and phenol bend corrosion thinning

After construction

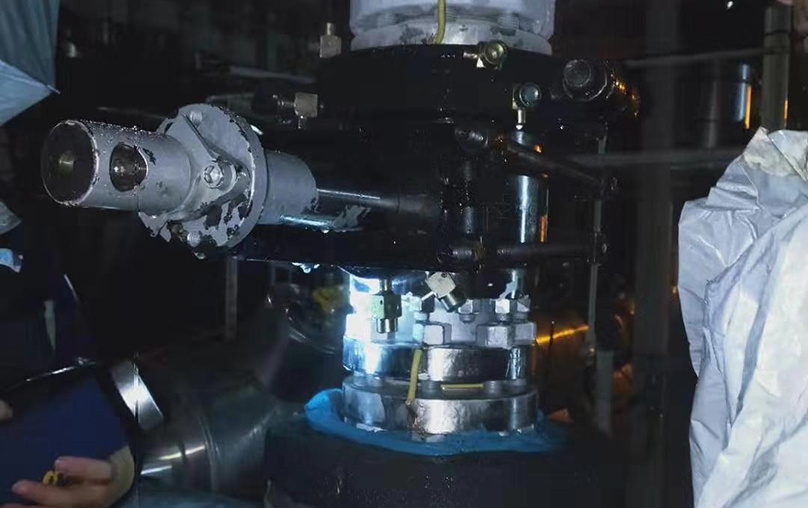

18(Pre construction) 8''x190kg 270℃ Steam Flange leakage

After construction

(Pre construction) 1'' 4kg ordinary temperature chlorine bottom drain corrosion leakage

After construction

(Pre construction) 16'' 40kg 300℃ Steam flange leakage

After construction

(Pre construction)16'' Change 6'' x6kg 180℃ Steam variable pipe erosion leakage

After construction

(Pre construction) 2'' x14kg 200℃ Steam Bend pipe erosion leakage

After construction

(Pre construction) 3''x3''x1x190kg 180℃ Steam three pass welding leakage

Construction site protection

After construction

(Pre construction) Rubber DN1400x4kg ordinary temperature seawater expansion joint flange leakage

After construction

(Pre construction) 4''x160kg 80℃ acid wastewater self sealing leakage of valve

After construction

(Pre construction) 1-1/2''x138kg 250℃ Steam bend pipe leakage

After construction

(Pre construction) 1''x40kg 190℃ Steam valve body leakage

After construction

(Pre construction) 20''x 80kg 60℃ co and wastewater flange diameter leakage

After construction

(Pre construction) 3''x300kg 140℃ ammonia and ethyl octanol flange leakage

After construction

(Pre construction)DN1000x4kg ordinary temperature cooling water expansion joint leakage

After construction

(Pre construction) 12''x8kg 180℃ Steam direct pipe erosion leakage

After construction

(Pre construction) 8''x 7kg 5℃ chilled water full package of butterfly valve body crack

After construction

(Pre construction) 8''x8''x1''x6kg 150℃ Steam three pass corrosion leakage

After construction

(Pre construction) 1-1/2''x180kg 200℃ Steam valve weld bead leakage

After construction

(Pre construction) 8''x8''x4''x14kg 200℃ Steam three pass weld crack leakage

After construction

(Pre construction) 6''x100kg 540℃ Steam high pressure valve packing leakage

After construction

(Pre construction) 4''x6kg 100℃ phenol tube corrosion leakage

(After construction) Fixture length 560mm

(Pre construction) DN1400x4kg ordinary temperature seawater flange leakage

After construction

(Pre construction)DN1200x4kg 250℃ hcl flanged disc root leaking in stone mill

(After construction) Local clamping device to stop leakage

(Pre construction) 4''x 4kg ordinary temperature acids and chlorine fluoroscopy flange leakage

(After construction)Special construction case of flanges leakage of perspective mirror

The division regularly conducts technical training and innovation

With pressure opening

With pressure opening

With pressure opening